Working With | Novesta

Our relationship with Novesta started in 2015 after a meeting in New York where Novesta suggested we collaborate with them. Later that year we needed footwear for our Spring Summer ’16 presentation, ‘Not Another Catwalk’, which they supplied. It seemed the ideal opportunity to take them up on their offer to collaborate.

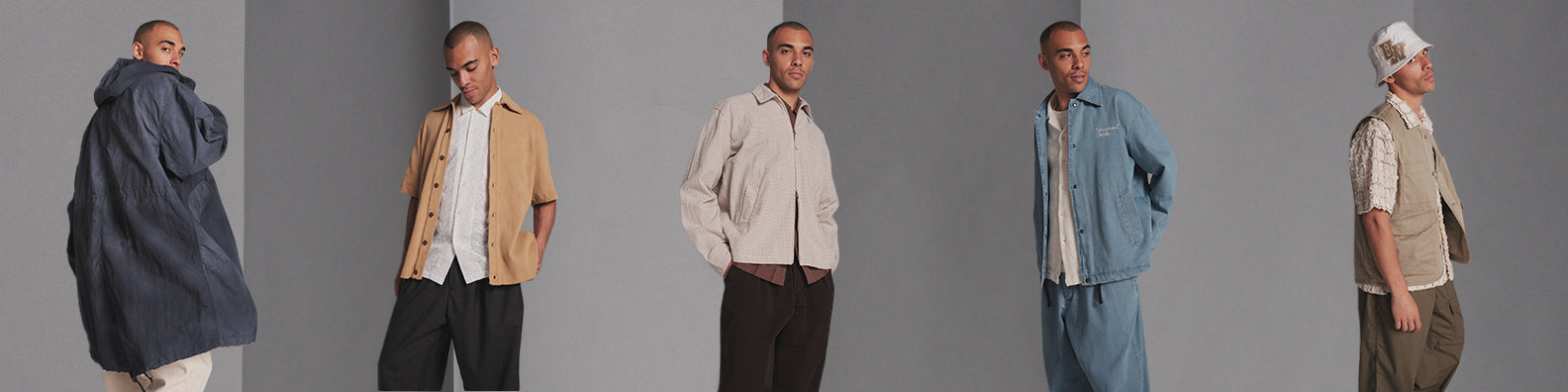

The first collaboration, using their Star Master and Dribble styles, were in ecru, navy and yellow canvas with a matching coloured sole which Novesta had not produced before. We also added an additional UW touch with a contrasting Navy heel stripe on all colours except Navy which had ecru. This contrast heel stripe has continued through all seasons and styles we have developed.

The following winter, thinking we needed a more robust fabric to combat the winter, saw us develop a version in 'Burel‘. A fabric made using an ancient technique of felting wool from the mountains of Portugal. We had used the fabric previously in one of our garments, the Mountain Parka. Although looking like standard felt, 'Burel' is first woven before being felted making it more robust and resilient to the elements.

We introduced a new style for Winter ’17, the Marathon. We found the silhouette when looking back into Novesta’s archives and found a running style trainer from the 70’s. As we have a few runners in the UW team this style had appeal. Most running trainers use technical fabrics so we thought this style would work well using an original 'technical' fabric, 'Burel' felt.

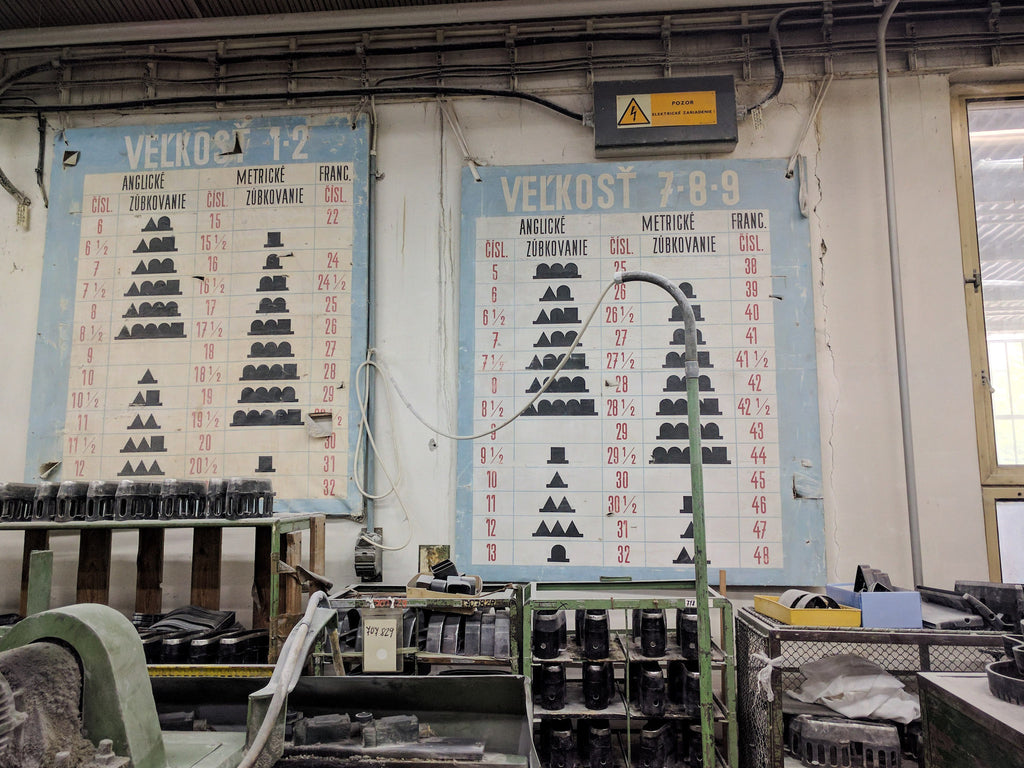

The appeal of Novesta and the reason we choose to collaborate with them was partly because of their manufacturing process. We visited Novesta earlier this year where they showed us the making process start to finish.

On a standard vulcanised shoe, the uppers are firstly glued to a rubber sole, with strips of rubber trim added around the outsole and then put in large ovens to bake to stick these two elements of the sole together and bond to the upper. On a Novesta shoe the upper is baked to the natural rubber sole with no glue, thereby forming a much longer lasting seal between the sole and the fabric uppers of the shoe and preventing cracking where the shoe bends because the sole is fully bonded to the upper. This signature process is evident by the blurred line between the rubber sole and upper giving a humble look but a high-quality finish. They are also unusual in having no production line, instead each shoe is individually handled from start to finish.

We enjoy working with Novesta both because of the product and the working relationship we have developed. They run a great factory and are genuine, nice people and we are always happy with the great shoes we make with them.

View our UW x Novesta collection here.

UWHQ