A visit to a Harris Tweed Mill.

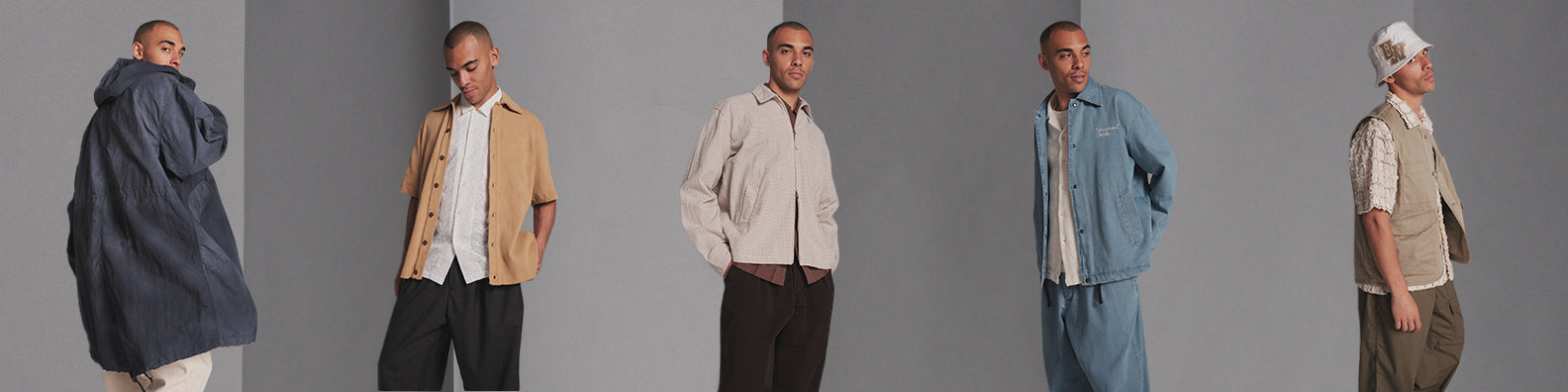

Browse the latest Harris Tweed pieces here.

Have you ever wondered what makes Harris Tweed fabric so special? While many people discuss the weaving process of Harris Tweed, not much thought is given to what happens before that.

It all starts way up North. The Outer Hebrides, known for its breathtaking landscapes, is home to the renowned Islands of Harris and Lewis, famous for producing one of the most highly regarded fabrics in the world: Harris Tweed. Earlier this year, during a visit to see Allan, the UW. customer service guru and David's brother, UW. founders Stephanie and David had the opportunity to explore the Outer Hebrides as part of their trip. Armed with their trusty boots, a packed lunch, and a warm flask, they set out for what would be an unforgettable experience.

Never ones to let an opportunity slip by, while on the Harris leg of their Hebridean journey, they paid a visit to the Kenneth Mackenzie Harris Tweed Mill. To their delight, the mill happened to be working on the fabric for our AW23 Bakers and Easy Over Jackets.

David Keyte shared his excitement, saying:

"Traveling 600 miles and experiencing a two-hour ferry ride to see your very own order of Harris Tweed being finished—after a lifelong love of this fabric, I finally got to see at least some of the process with the amazing people at Kenneth Mackenzie Harris Tweed."

During their visit, Stephanie and David received a tour of the Kenneth Mackenzie mill from Donna and her son Andy and were guided through the step-by-step production process. Transforming raw wool into beautiful yarn begins with selecting the finest fleece and wool. This raw material is then dyed in enormous vats, each containing a different hue, creating a vibrant spectrum of colours. After dyeing, the wool is carefully dried on a conveyor belt, ensuring it's ready for the next stage. The secret to achieving the perfect shades lies in individual recipes for each colour, with a mysterious room where the raw, dyed fleece blending process takes place.

Here, carding machines, (similar to the ones Stephanie's dad used to make), come into play. They tease out the fibres and seamlessly mix the various colours. Once the blend is perfected, the wool is spun onto cones, ready to form the warps and wefts, setting the stage for the weaving machine to work its magic. In this intricate dance of craftsmanship, each step contributes to the creation of this remarkable yarn, a testament to the skill and dedication of artisans like Kenneth McKenzie. Once this winding process is finished, the beam is prepared for distribution to skilled islanders, who will use it to weave intricate and wonderful designs on their looms.

It's fair to say that our Harris Tweed is a popular choice, but if you're worried about wearing the same thing as your mate, you need not be concerned, as each one is unique, despite following the same recipe. It's the little things, the subtle nuances, the slight differences—those imperfections that come from being touched by people's hands—that make handmade products like Harris Tweed all the more interesting.

So, next time you hold one of our Harris Tweed pieces in your hands, once you know the journey it took, you'll see all the colours within it and appreciate the skilled hands of artisans like Kenneth McKenzie.

Browse the latest Harris Tweed pieces here.